Barb tape, also named as razor tape, concertina wire or razor wire, is manufactured from mild steel wires and consist of a continuous steel strip that is enclosed with sharp blades. All coils are clipped together to obtain a stable and homogeneous network. It is an alternative but has higher security grade than the barbed wires.

Barb tape is regarded as effective deterrent for intruders and it adds an anti-climb quality to almost all security fences and black walls.

Benefits

- An effective deterrent to intruders and prevent them from climbing the fence or walls.

- Various materials and corrosion resistance coatings guarantee the long lifetime.

- Simple installation and no need of complex machines and tools.

- A large variety of configurations and materials is available on specific demand providing different security level for your projects.

Main Market

- Europe

- MENA (Middle Eastern & Northern Africa)

- United Kingdom

- Americas

- South & Central Africa

- APAC (Asia Pacific)

Materials & Coating

- Heavy Galvanized Steel Wire (zinc coating ≥ 245 g/m2)

- Galvanized Steel Wire (zinc coating ≥ 60 g/m2)

- Stainless Steel Wire

| Blades | ||||

|---|---|---|---|---|

| Heavy Galvanized | Galvanized | Stainless Steel | ||

| Core Wire | Heavy Galvanized | √ | √ | |

| Galvanized | √ | √ | √ | |

| Stainless Steel | √ | |||

Blade Types

Barbed tape can be divided into two main blade series: Concertina Barbed Tape (CBT) and Barbed Tape Obstacle (BTO).

And Five main and popular types are also recognized as fish hook blade, tear blade, long blade, medium blade and short blade.

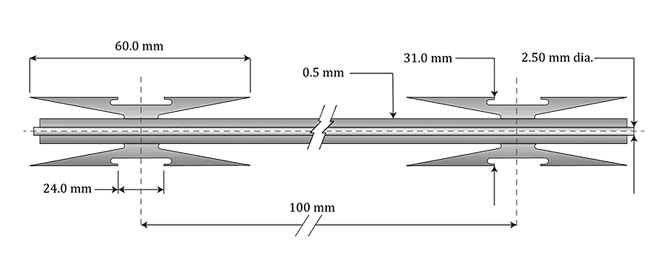

| Blade Type | Drawings | Barb Thickness (mm) | Barb Length (mm) | Barb Width (mm) | Barb Spacing (mm) | Core Wire Diameter (mm) |

|---|---|---|---|---|---|---|

| CBT-60 |

|

0.5 ± 0.05 | 60.0 ± 2 | 31 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

| CBT-65 |

|

0.5 ± 0.05 | 65 ± 2 | 21 ± 1 | 100 ± 2 | 2.5 ± 0.1 |

| BTO-30 |

|

0.5 ± 0.05 | 30 ± 1 | 18 ± 1 | 45 ± 2 | 2.5 ± 0.1 |

| BTO-22 |

|

0.5 ± 0.05 | 22 ± 1 | 16 ± 1 | 35 ± 1 | 2.5 ± 0.1 |

| BTO-10 |

|

0.5 ± 0.05 | 10 ± 1 | 13 ± 1 | 25 ± 1 | 2.5 ± 0.1 |

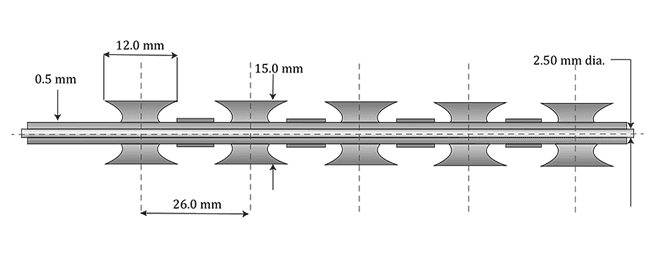

| BTO-12 |

|

0.5 ± 0.05 | 12 ± 1 | 15 ± 1 | 26 ± 1 | 2.5 ± 0.1 |

| BTO-18 |

|

0.5 ± 0.05 | 18 ± 1 | 15 ± 1 | 33 ± 1 | 2.5 ± 0.1 |

| BTO-28 |

|

0.5 ± 0.05 | 28 ± 1 | 15 ± 1 | 45 ± 1 | 2.5 ± 0.1 |

Coil Loop Specifications

| Outer Diameter | Loops | Extended Length | Blade Type | Note |

|---|---|---|---|---|

| 300 mm | 33 | 4–6 m | CBT- 60, 65 | Single coil |

| 450 mm | 33 | 7–8 m | CBT- 60, 65 | Single coil |

| 500 mm | 56 | 12–13 m | CBT- 60, 65 | Single coil |

| 700 mm | 56 | 13–14 m | CBT- 60, 65 | Single coil |

| 960 mm | 56 | 14–15 m | CBT- 60, 65 | Single coil |

| 450 mm | 56 | 8–9 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 500 mm | 56 | 9–10 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 600 mm | 56 | 10–11 m (3 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 700 mm | 56 | 10–12 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 800 mm | 56 | 11–13 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 900 mm | 56 | 12–14 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| 980 mm | 56 | 14–16 m (5 clips) | BTO- 10, 12, 18, 22, 28, 30 | Cross type |

| * JINSHI can manufacture other special requirements of coil type or clip quantity upon request | ||||

Applications

- Prison

- Ship

- Factories & industrial sites

- Military installation

- Refineries

- Government buildings

- Power stations

- Airports

- Temporary barriers

- Police stations

- Farmland

Prison safety guard

Military site defense

Airport safety guard

Residence safety guard